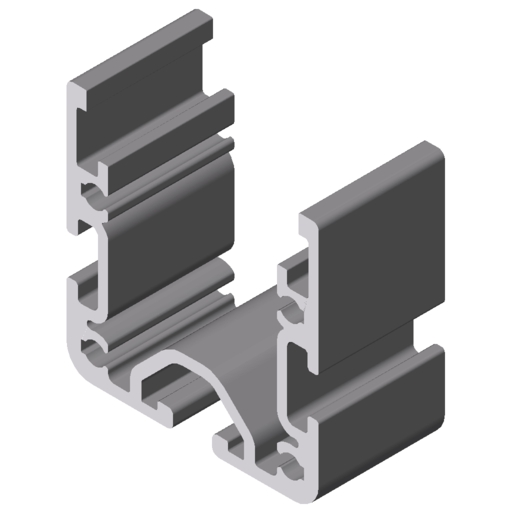

This roller conveyor is full of ingenious details. Thanks to its rigid aluminium profile, Roller Conveyor 6 40x40 E D30 can carry heavy loads – even over long distances. It is supplied preassembled and ready for immediate use.

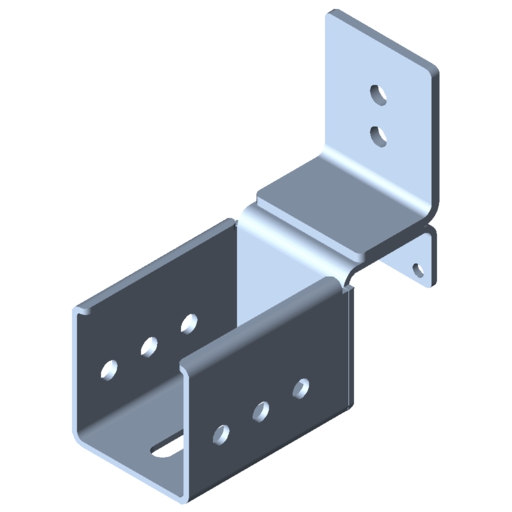

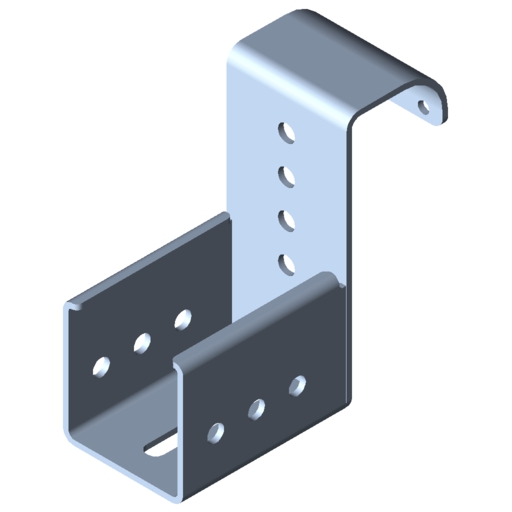

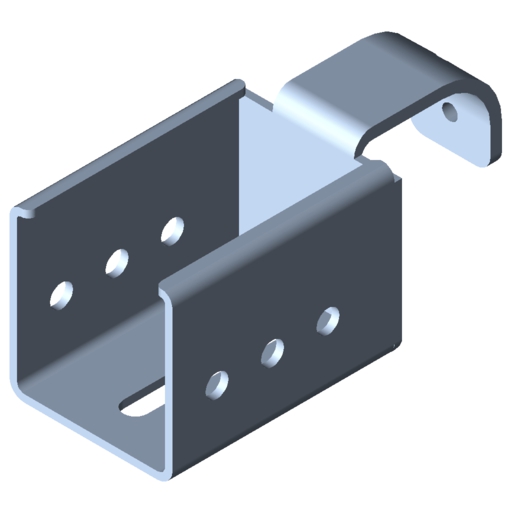

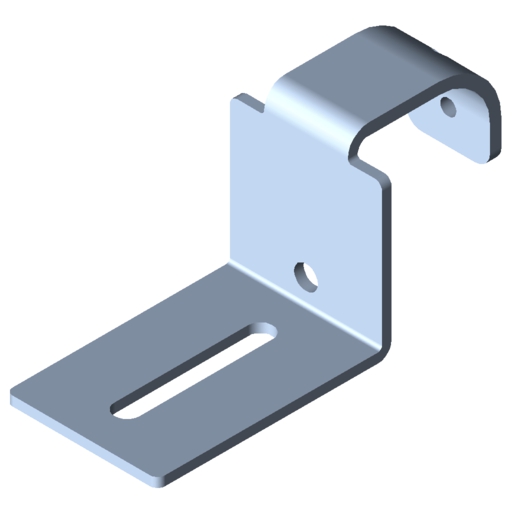

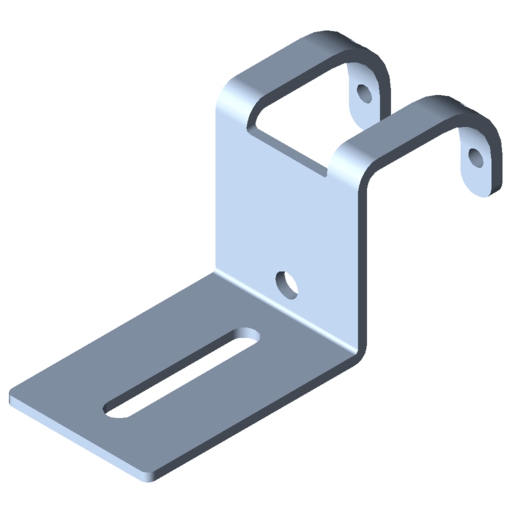

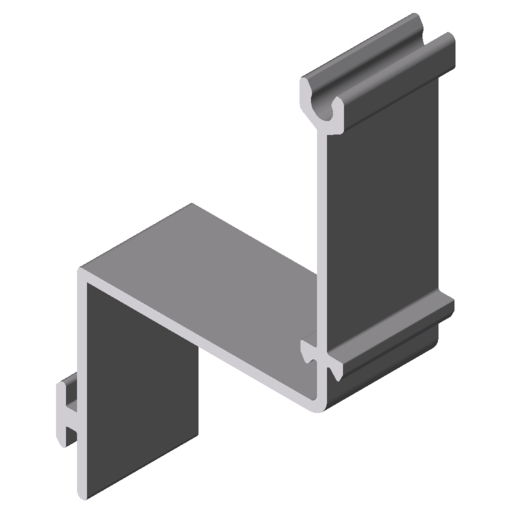

The underside of the rail of Roller Conveyor 6 40x40 E features a Line 6 profile groove that can be used to secure the conveyor line to the frame. This friction-based connection has a long-lasting hold and contributes to the stability of the frame. Even when the roller conveyor projects beyond the frame, it will not slip. What’s more, additional components or panel elements can be fitted to the underside of the roller conveyor to protect other transport lines underneath from falling debris and soiling.

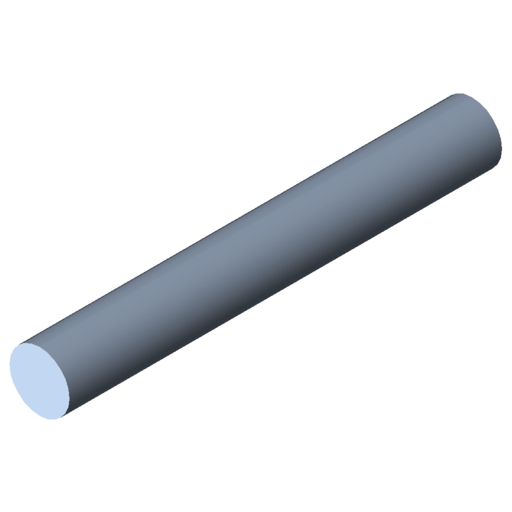

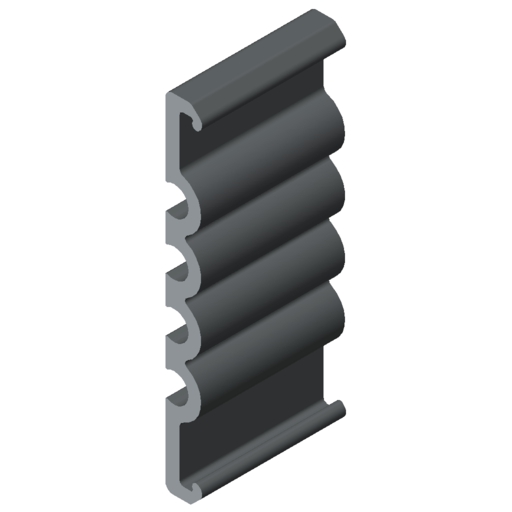

Roller Conveyor 6 40x40 E D30 is available in customised lengths fitted with Castors D30 (with or without flanged wheels) and side-by-side offset Castors D30/2 or Rollers D11. The tight roller element spacing of Rollers D11 provides continuous support for small and sensitive goods along the entire line. This minimises vibration and ensures boxes with soft bases can also be moved from A to B.

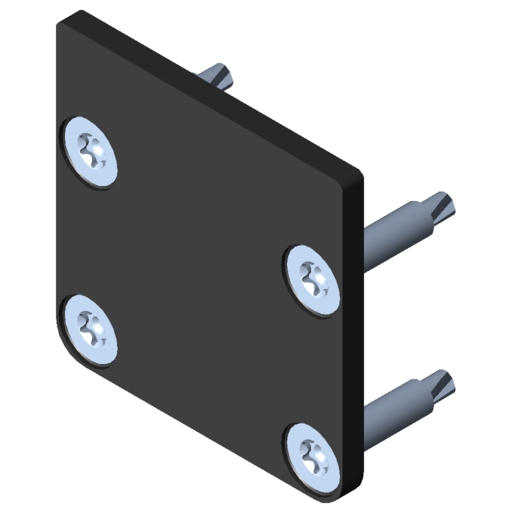

If necessary, individual roller elements can be replaced without having to use tools or take out other roller elements first.

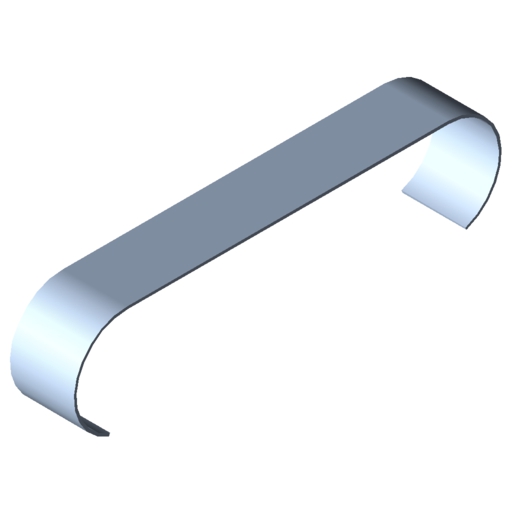

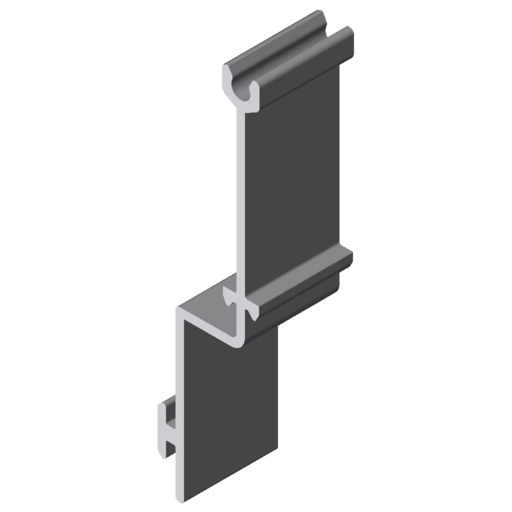

To make sure workpieces stay on track, sturdy aluminium Guide Rails can also be added. Thanks to a special groove, installation is especially straightforward. The Guide Rails boost the rigidity of the conveyor line. Additional Slide Strips stop sensitive goods from being scratched.

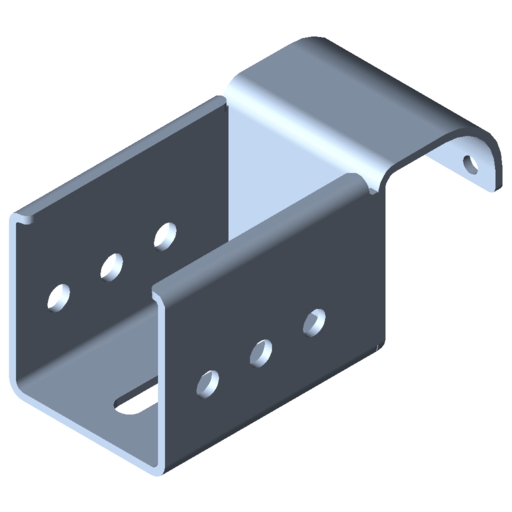

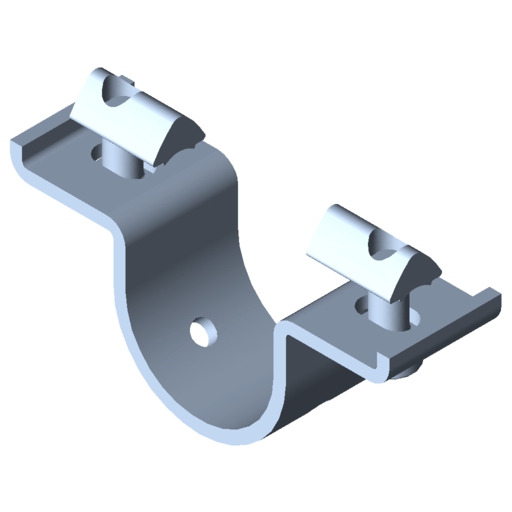

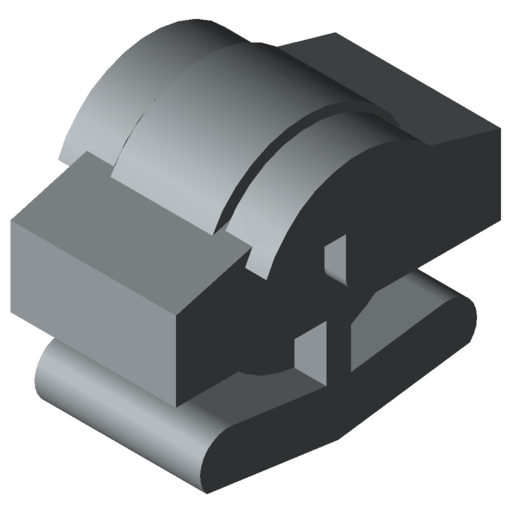

Braking Castors can be used to regulate the running speed of containers regardless of their weight. This helps establish a smooth and even flow of materials and is kinder on the frame and transported goods.

Note: Roller Conveyor 6 E D30 is also available in a double-width variant as Roller Conveyor 6 80x40 E D30.