Attributes

Details

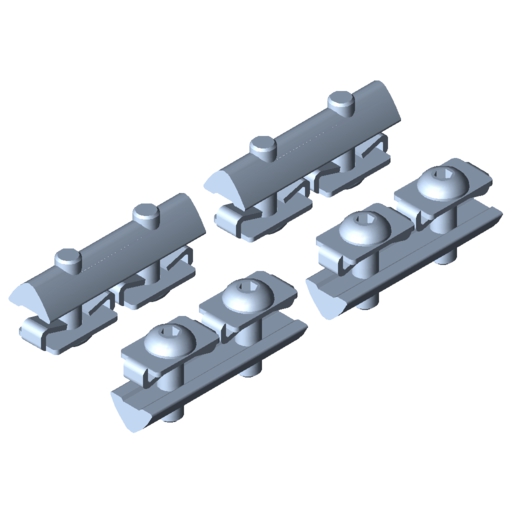

Accessoires / Service

1 set

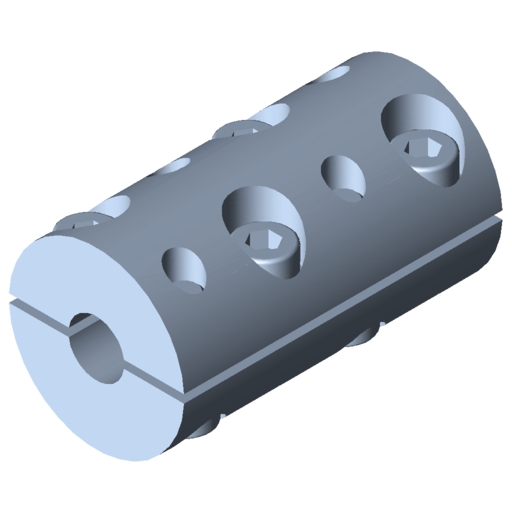

0.0.472.28

1 set

0.0.463.72

1 pce.

0.0.026.30

No online account yet?

RegisterPlease log in to use this feature

Parts list import

Cart-History

CAD Downloadcenter (0)

For more than 30 years, engineers around the world have been relying on the MB Building Kit System because it presents solutions that simply work. The modular components can be combined in a virtually unlimited number of variations, helping you turn your ideas into reality.

For more than 30 years, engineers around the world have been relying on the MB Building Kit System because it presents solutions that simply work. The modular components can be combined in a virtually unlimited number of variations, helping you turn your ideas into reality.

The item MB Building Kit System is the solution for all design and construction tasks involving factory equipment engineering. It can be used to build everything from simple frames to fully automated production lines.

The item work bench system for manual production: Optimum work bench design for manual work benches in industrial and office environments – whatever the task, the work bench system from item has the ideal solution for manual production operations.

D30 – the profile tube system for building sophisticated, solution-oriented factory equipment fast. It is exactly what you need to implement Japanese production philosophies in your plants, optimise production processes and thus lower costs.

Whether one large platform, an all-round assembly platform or a simple maintenance platform, the Stairway/Platform System can be used to build working areas at any height. Because TPS is compatible with the item MB Building Kit System, users can make the most of the entire range of accessories, including enclosures and guards, doors, profiles, floor elements, etc. TPS makes stairways and platforms integral components of machine bases.

Clean lines on the outside, ingenious details on the inside – Line XMS meets all the requirements of modular series production.

The Protective Enclosure System from item satisfies all requirements for continuous machine guards. It has been engineered on an entirely modular basis using components from the MB Building Kit System and can be adapted to suit the relevant machine and the necessary protective function perfectly.

The item Automation System is a comprehensive turnkey solution for linear technology. It comprises ready-to-install Linear Units that are delivered with drive elements, slides and accessories included. Install and go – automation really can be that easy.

Discover all new components in a short Overview or in the latest New Products Catalogue – available as a practical download online.

We help you plan your projects. Use our intelligent configurators, our application examples or contact us directly!

We help you plan your projects. Use our intelligent configurators, our application examples or contact us directly!

Our intelligent configurators are fast, easy-to-use tools for designing custom projects. Parts lists and 3D PDFs speed up planning and coordination considerably.

Discover pattern solutions in our application examples. As registered item customer you can download CAD data and 3D PDFs directly.

We help you plan your projects, customised and highly efficient. Submit an enquiry now.

Your ideas are worth it.

For us, that means living up to the high quality standards we set for our products and services. Read more about us!

Your ideas are worth it.

For us, that means living up to the high quality standards we set for our products and services. Read more about us!

We are happy to welcome you at our stand!

Find your perfect distributor - worldwide!

The features that characterise quality products are functionality and excellent design. That is why item places a heavy emphasis on design from the very outset.

Discover our comprehensive range of services. Get an overview of what we offer and find out how you can take advantage of the Online Shop, various online tools and configurators, the CAD Download Center and many other features.

Discover our comprehensive range of services. Get an overview of what we offer and find out how you can take advantage of the Online Shop, various online tools and configurators, the CAD Download Center and many other features.

Whether you’re looking for different product catalogues in different languages, you’re in the right place! The filter function and the option to group together downloads via the reading list are particularly practical features that give you quick access to the content you want

Get your CAD Data in 2 simple steps.

The item Online Shop provides you with CAD models for all conventional formats. You can find your saved CAD data and download it in just a few steps.

Registering with item offers you numerous additional benefits. Make the most of the Online Shop’s user-friendly features including CAD downloads, the parts list import function, the shopping cart view and many others.

Boasting more than 4000 products, the item Online Catalogue is literally the one-stop shop for aluminium profiles and item accessories and even includes item CAD data!

Get further education - when, where and how you want!

- item Academy: Free online training at any time

- Lean training(cooperted): Lean training close to practice in a realistic production environment

Welcome to the item online catalogue. Find additional information to more than 4000 products of the item building kit system.

The item MB Building Kit System is the solution for all design and construction tasks involving factory equipment engineering. It can be used to build everything from simple frames to fully automated production lines.

The item work bench system for manual production: Optimum work bench design for manual work benches in industrial and office environments – whatever the task, the work bench system from item has the ideal solution for manual production operations.

D30 – the profile tube system for building sophisticated, solution-oriented factory equipment fast. It is exactly what you need to implement Japanese production philosophies in your plants, optimise production processes and thus lower costs.

Whether one large platform, an all-round assembly platform or a simple maintenance platform, the Stairway/Platform System can be used to build working areas at any height. Because TPS is compatible with the item MB Building Kit System, users can make the most of the entire range of accessories, including enclosures and guards, doors, profiles, floor elements, etc. TPS makes stairways and platforms integral components of machine bases.

Clean lines on the outside, ingenious details on the inside – Line XMS meets all the requirements of modular series production.

The Protective Enclosure System from item satisfies all requirements for continuous machine guards. It has been engineered on an entirely modular basis using components from the MB Building Kit System and can be adapted to suit the relevant machine and the necessary protective function perfectly.

The item Automation System is a comprehensive turnkey solution for linear technology. It comprises ready-to-install Linear Units that are delivered with drive elements, slides and accessories included. Install and go – automation really can be that easy.

Use the latest innovations from item to complete engineering projects more efficiently. This overview lets you browser all the new components including the technical details.

Welcome to the item online catalogue. Find additional information to more than 4000 products of the item building kit system.

Find your nearest contact

No online account yet?

RegisterPlease log in to use this feature

Parts list import

Cart-History

CAD Downloadcenter (0)