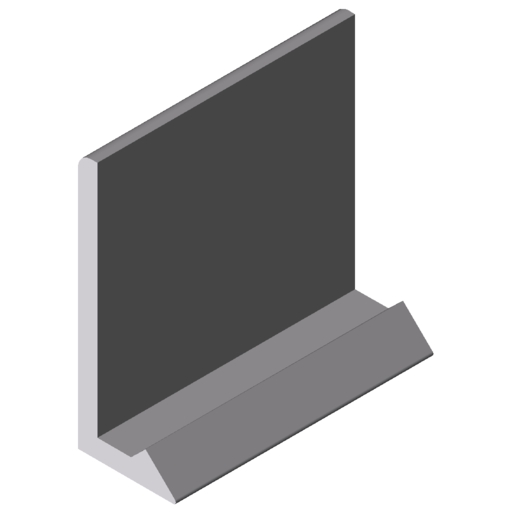

Thanks to the use of electron beam hardening, Plastic Pro features a non-porous, impact-proof and easy-to-clean surface that is suitable for demanding applications in cleanrooms and laboratories.

The hardened surface exhibits excellent chemical resistance to aggressive cleaning agents. The surface is also highly resistant to hydrogen peroxide gas (H

2O

2).

What’s more, the HPL panels exhibit excellent abrasion resistance and impact strength right up to their edges. Since Plastic Pro is not susceptible to scratching or corrosion, it can be used as an alternative to stainless steel surfaces in work areas that are heavily used.

The sealed, unbroken surface permanently reduces the outgassing of volatile organic compounds (VOCs).

Note: Panel elements made of Plastic Pro must be stored and transported lying flat until they are installed.

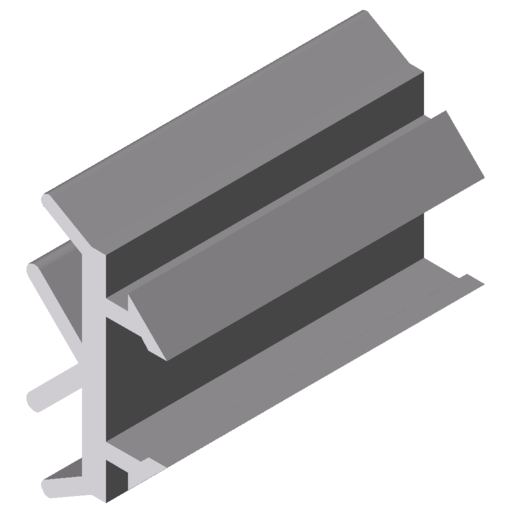

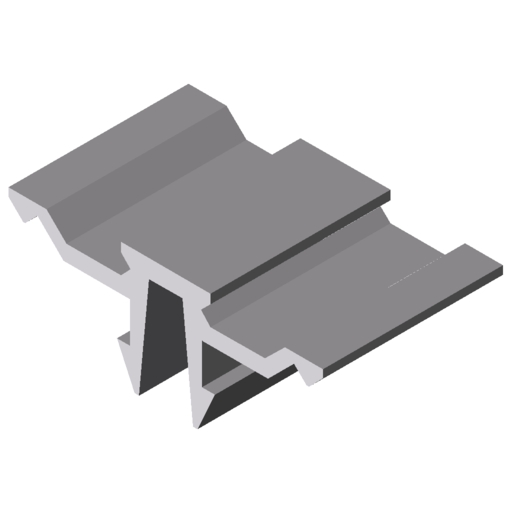

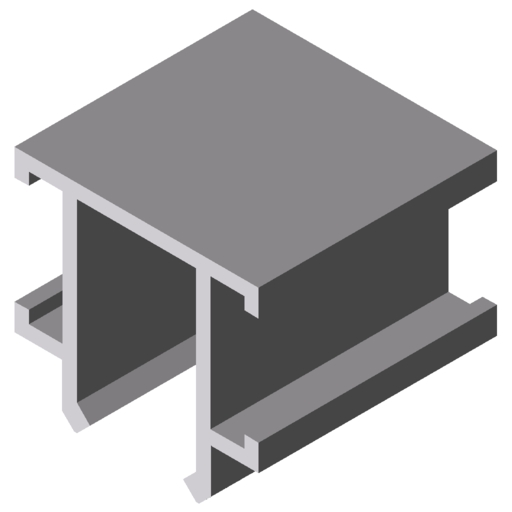

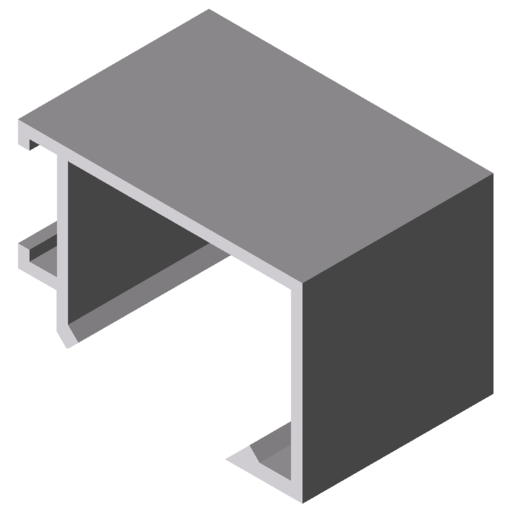

The item Fixing System is a modular system for fixing in place panels. It is particularly suitable for use in cleanrooms but can also be used to build walls and ceilings. When used together, Base Profiles, Angle Strip covers, Rebate Profiles and Lip Seals help to create easy-to-clean surfaces of the type that are needed in a cleanroom.

The Fixing System can also be combined with a range of panel elements as well as Lines X and XMS. There is no need to cut out sections on profiles or panels.

Note: To ensure easy installation, aluminium profiles for panel-fastening should be ordered 0.5 mm shorter than the calculated cut length.