From a trolley to a train! Drawbar D25-686 links transport trolleys together or can form a connection with a tugger – so that more products can be moved than ever before.

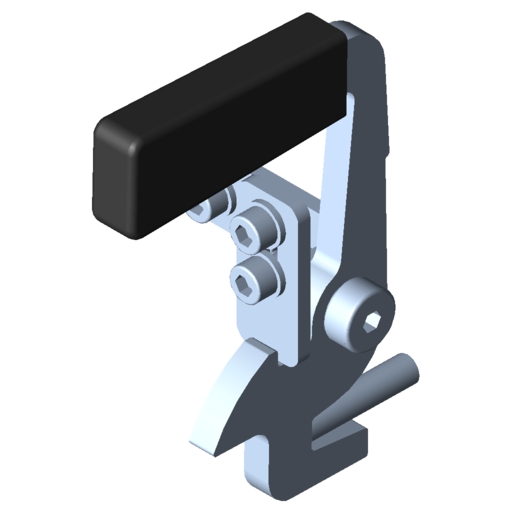

The Drawbar is available in two designs with safety functions and useful accessories. Drawbar D25-686, Self-Lifting is particularly ergonomic and back-friendly. A stable spring continuously pushes the Drawbar up, which has two benefits: It ensures it is easy to couple and uncouple the Drawbar using your foot. There is no need to bend over awkwardly or carry out any complicated fastening sequence. When uncoupled, the Drawbar automatically folds up to clear the working area.

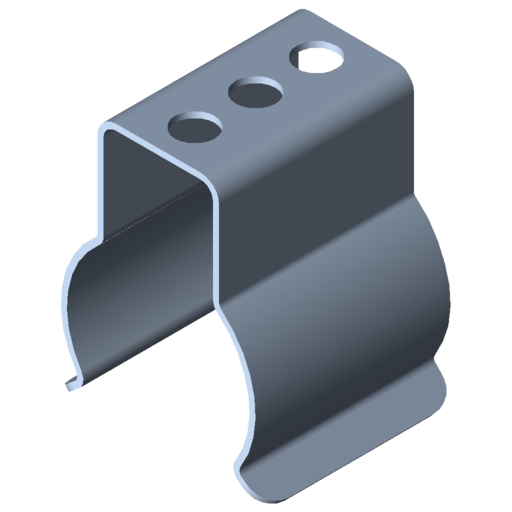

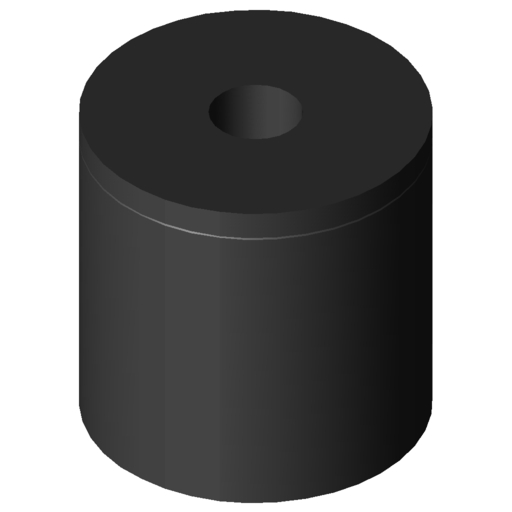

To ensure safe operation, the Impact Buffer on both models stops the Drawbar from hitting the trolley when folded up. Two spring clips hold the raised Drawbar in place.

When using Drawbar Locking Lever 38, the Drawbar locks in place so that it can’t be released unintentionally. When lowering the Drawbar, the optional Drawbar Stop 32 ensures it does not drop to the floor and stops users pressing it too far down with their foot. An elastic buffer brings the Drawbar to a stop in plenty of time.

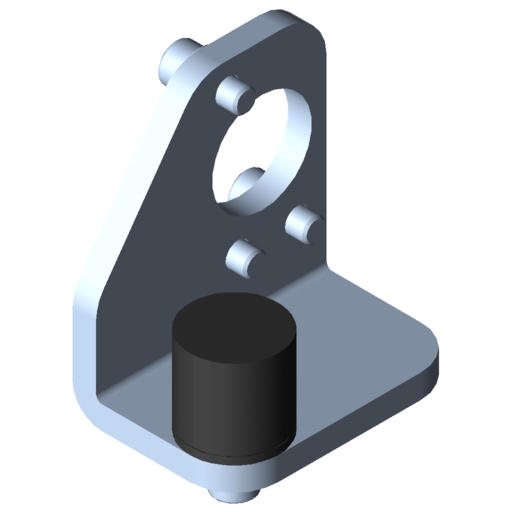

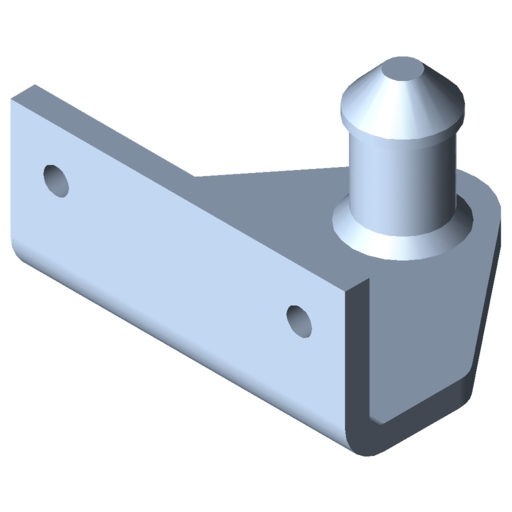

When using the version of Drawbar D25-686 without the self-lifting mechanism, the pin of the coupling should point upward. The dead weight of the steel Drawbar ensures that the connection holds. Because there is no spring-loaded lifting mechanism, the Drawbar has to be moved into its park position by hand.

Due to the high tensile loading generated during transport, Profile 8 80x40 is best suited for building the framework of a trolley.